NVH Systems

Rubber to metal composite bearings have become indispensable as vibration dampers.

For commercial & passenger vehicles

Bearing solutions

Bearing solutions for conventional gasoline and diesel powertrains, along with engine mount systems with low high frequency dynamic stiffness designed for electric vehicles. Additionally, we offer innovative hydraulic engine mounts and polyamide components, providing our customers with a superior level of comfort.

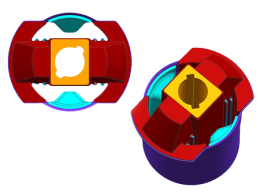

Aluminum Die Casting Inner Core

Connection to the chassis. Provision of internal travel limits. Stiffening of structural components.

Elastomeric suspension spring

Support of the motor load. Support against dynamic excitations.

Use of highly elastic compounds of:

- Natural rubber

- Silicone

- EPDM

Plastic outer part

Calibration when pressing into the motor housing. Ensuring a tight fit of the bearing. Different versions in PA6, PA6.6 with different glass fiber contents.

Got Questions?:

nbjx Europe

+49 811 998 535 0

In the field of elastic suspension and vibration damping, NBJXEurope offers a wide portfolio of components.

Strict regulations on vehicle emissions, as well as dwindling resources and constantly rising energy costs, are forcing the automotive industry to come up with innovative solutions. As a result, hybrid drives and pure electric drives are becoming increasingly important. With our long-standing know-how in the field of NVH, we are one of the world's leading suppliers of engine mounting systems for combustion engine, hybrid and electric vehicles. With our solutions, we offer optimal ride comfort for a wide range of vehicle types.

With the emergence of the megatrend of electromobility, we have noticed changing requirements. For example, mechanical high-frequency excitations occur primarily in electric motors. From our development expertise for conventional gasoline or diesel vehicles, we successfully work out innovative solutions with our customers. To this end, we offer optimally adapted unit mounts for all drive concepts. In addition to specially developed elastomer compounds, we derive design concepts with optimized geometry. In this way, our components contribute to an increased range in electric vehicles, for example, through the consistent use of lightweight construction.

Our experts develop fiber-reinforced polyamide as well as aluminum, steel and other materials in combination with elastomer geometries tailored to customer-specific requirements.

NBJX Northamaerica as a business unit of Jianxin Zhao's Technology Group Co. Ltd. thus offers a broad spectrum of development competencies as a system provider. Thus we offer complete solutions for the worldwide operating automotive manufacturers.

Hydromount - Structure

Structure of a hydromount as an example (from top to bottom):

- Elastomer support spring for connection to the engine

- Throttle system to provide high damping values

- Rolling diaphragm to accommodate the pumped fluid

- Glass fiber reinforced polyamide cap

Examples of use

Hydraulic engine mount

Hydraulic engine mounts are characterized by a high degree of damping.

more...

Hydraulic engine mount

Hydraulic engine mounts carry static and dynamic loads that are introduced into the vehicle by the power unit.

In low and high frequency ranges, hydraulic engine mounts provide a high degree of vibration isolation and at the same time maximum damping.

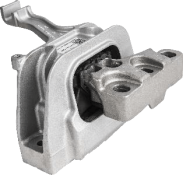

Conventional engine mounts

Conventional engine mounts carry static and dynamic engine loads over the entire vehicle life and isolate vibrations in the low and high frequency ranges.

more...

Conventional engine mounts

Conventional engine mounts can have a wide variety of designs. In addition to static loads, they also absorb dynamic loads. In low and high frequency ranges, conventional elastomeric motor mounts provide a high degree of vibration isolation. In addition to the design, the material properties of the elastomer material are an important design criterion.

Bush Bearings

Bush bearings get more and more important by the usage in electric vehicles.

more...

Bush bearings

Bush bearings are a separate form of both hydraulic and conventional design. Depending on customer requirements, bush bearings are mainly used in the chassis area or as engine bearing systems for electric vehicles.

Tuned Mass Dampers

Tuned Mass Dampers reduce vibrations in many areas of the vehicle, from the tailgate to the steering wheel.

more...

Tuned Mass Dampers

Tuned Mass Dampers are used to reduce vibrations in a wide variety of vehicle areas. Used as tailgate absorbers, they reduce rattling or droning noises from the tailgate. Steering wheel absorbers also optimize the comfort behavior in the vehicle interior.

Torque struts

Torque struts dampen the influence of torques generated by engine rolling motions.

In doing so, they limit unit movements during the transmission of engine loads.

more...

Torque struts

Torque struts are used to support the torque input of a power unit. They absorb torques from the drive train during acceleration or braking. Torque supports thus limit engine rolling motions.

Adaptive engine mounts

Adaptive engine mounts offer an extension of classic hydraulic engine mounts by integrating a switching function. This switching function allows different adaptations to be made with regard to damping behavior.

more...

Adaptive engine mounts

It contributes to the overall rigidity of the vehicle and absorbs the forces and torque of the engine-transmission unit.

By using glass fiber-reinforced polyamide instead of aluminum, the weight of the part was reduced by 50 percent. As the central component of the rear axle, the transmission cross member made of glass fiber-reinforced polyamide is about 25 percent lighter than die-cast aluminum versions.

Exhaust system suspension

The exhaust suspension fulfills several tasks. It reduces the transmission of structure-borne noise from the exhaust system to the body by means of targeted component tuning. At the same time, it reduces the movements of the exhaust system due to the component characteristics. High temperature resistance and durability are crucial.

more...

Exhaust system suspension

Exhaust isolators must perform in extreme temperature environments and meet NVH requirements as well as durability and strength specifications. Our high-temperature elastomers with silicone content and our EPDM-based compounds are designed and engineered to meet the specific requirements of each application.

Dual Compound

Dual compound technology offers a combination of the benefits of conventional and hydraulic bushings in one component, improving component performance.

more...

Dual Compound

The additional cost of dual compound technology is limited primarily to the additional cost of the additional waste from the second mold feed system and a minor increase in tooling to accommodate the dual compound design. The technology was developed in large part to bridge the cost and functionality of conventional and hydraulic bushings.

The technology can be used in a wide variety of components, such as.

- Twist-axle bushing

- Compound control arm axle bushings

- Trailing arm bushing

- Wishbone bushing

- Subframe bearings

- Torque arm

- Power unit bearing

Transmission bearing

The transmission mount is the most important connecting element between the transmission and the body of a vehicle. They support the transmission's own weight and limit driveline movement on the transmission side in the engine compartment. The bearing dampens vibrations and absorbs shocks caused by an uneven road surface.

more...

Transmission bearing

Limiting driveline movement while isolating the high-frequency vibrations typically generated by transmission gears is achieved through component design and advanced compound development to lower dynamic hardening.

Chassis Bushings

more...

Chassis Bushings

Chassis bushings, whether single, double or triple bound, are designed to provide the necessary mobility while guiding in multi-link suspensions while meeting NVH, strength and durability requirements.

Top Mounts

Top Mounts are used as the interface between the McPherson strut and the body. Among other things, it enables low-friction rotation of the strut.

more...

Top Mounts

Top mounts, whether for shock absorbers, spring-damper struts or McPherson struts, must work seamlessly with the suspension system in the chassis and also absorb the maximum loads that occur in rough road conditions. Elastomeric compounds are available to minimize noise transmission from the road surface while being designed to withstand the harshest loads from the chassis.

Subframe Mounts

more...

Subframe Mounts

For the front engine mount, the subframe mounts must work in conjunction with the engine mounts and driveline suspension to isolate engine noise and road excitation. In today's situation, where weight is crucial for fuel economy, high-tech lightweight plastics and the use of lightweight aluminum can play a decisive role in reducing fuel consumption.

Also of interest?

Manufacturing

We develop the right solutions with our customers on site and have them produced in our plants in China.

Testing and validation

Extensive testing and validation of results are the main components of successful manufacturing for us.

CAE: CAD & FEM

State-of-the-art technology and test tracks on the computer. Resource-saving and quick to implement.